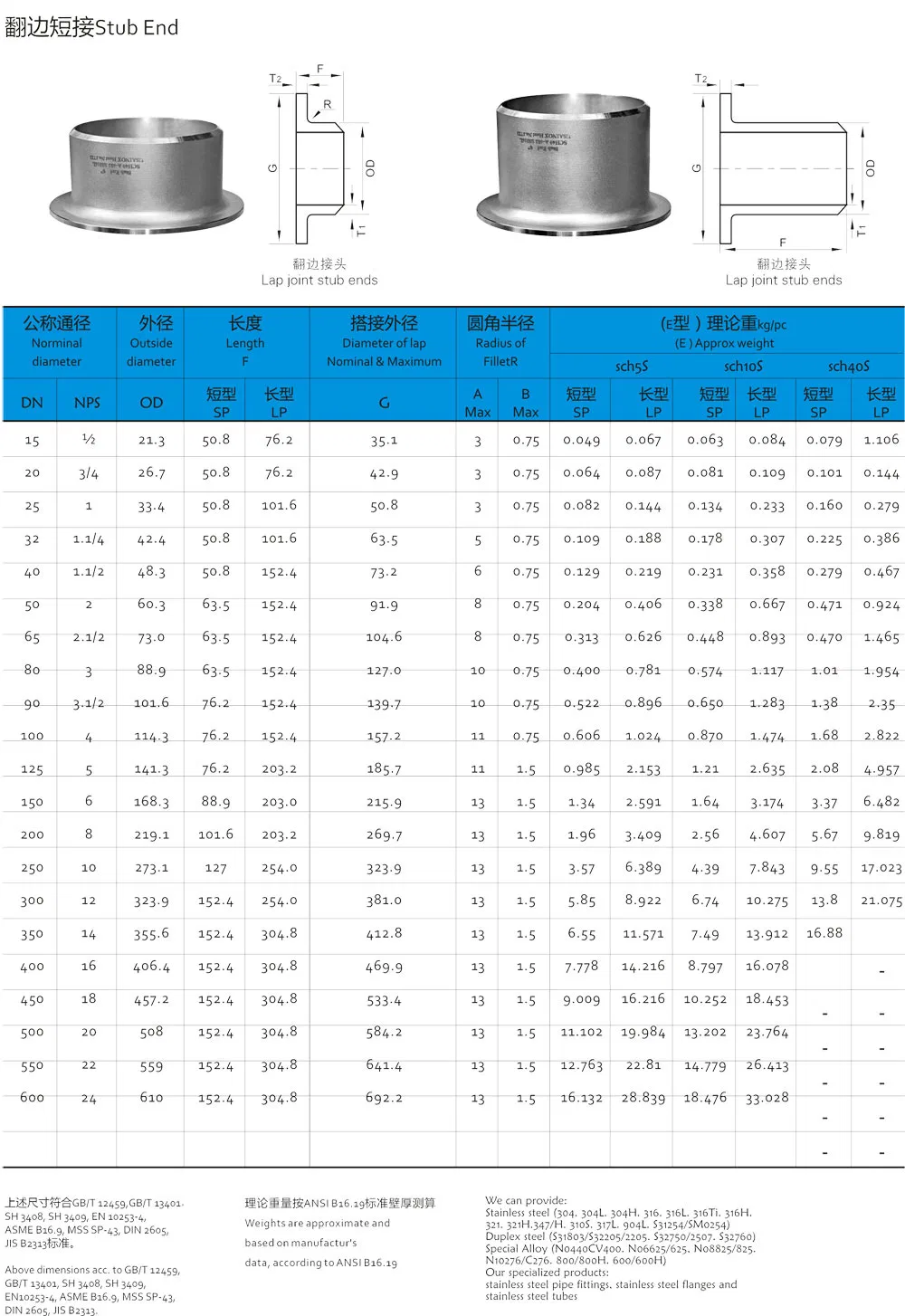

SS304 Stainless Steel Pipe Fitting Bw Seamless Pipe Stub End

SS304 stainless steel pipe fitting BW seamless pipe stub end Cap 45 degree elbow Tee Elbow The 90 degree Long Radius Elb

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | studend |

| Technics | Hot-pressed |

| Color | Silver |

| Thickness | Sch5 to Sch160 |

| Product Name | Seamless Pipe Stub End |

| Standard | ASME B16.9 |

| Transport Package | Plywooden Case |

| Specification | 1/2" - 48" |

| Trademark | Fly |

| Origin | Zhejiang Province, China |

| HS Code | 7307230000 |

| Production Capacity | 50000tons/Month |

Product Description

SS304 stainless steel pipe fitting BW seamless pipe stub end

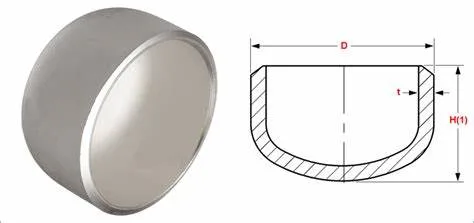

Cap

| Norminal Pipe Size | Outside Diameter at Bevel | Length | Limiting Wall Thickness For Length E | ||

| DN | Series A | Series B | E | E1 | |

| 15 | 21.3 | 18 | 25 | - | - |

| 20 | 26.9 | 25 | 25 | - | - |

| 25 | 33.7 | 32 | 38 | - | - |

| 32 | 42.4 | 38 | 38 | - | - |

| 40 | 48.3 | 45 | 38 | - | - |

| 50 | 60.3 | 57 | 38 | 44 | 5.5 |

| 65 | 76.1 | 76 | 38 | 51 | 7.0 |

| 80 | 88.9 | 89 | 51 | 64 | 7.6 |

| .. | .. | .. | .. | .. | .. |

| 500 | 508.0 | 529 | 229 | 254 | 12.7 |

45 degree elbow

| Model No. | 1/2"-48" |

| Material | Stainless steel(304,304L,316,316L,321,321H,310S,347H) |

| Type | Butt weld and seamless pipe fitting |

| Size | Seamless Fittings 1/2-20(DN15-DN500),Welded Fittings 1/2-48(DN15-DN1200) or as Customer's requirement |

| Thickness | SCH5S-SCH80S |

| Standard | ASME B16.9,DIN 2605,JIS GB/T12459,GB/T13401 |

| Application | For use in the petroleum,smelting,foodstuff,power,papermaking,chemical,medical equipment,aviation,boiler heat exchanger and other fields |

| Surface Treatment | Polishing,sand rolling,sand blasting or as per customers' requirement |

Norminal Diameter | Outside Diameter | Center to end | Center to Center | L/R Elbow Approx weight | |||||||

| DN | NPS | OD | B | A | O | sch5S | sch10S | sch20S/LG | sch40S/STD | sch80S/XS | sch80 |

| 15 | ½ | 18 21.3 | 16 | 38 | 76 | 0.04 0.05 | 0.05 0.06 | 0.06 0.07 | 0.06 0.08 | 0.08 0.10 | 0.08 0.10 |

| 20 | ¾ | 25 26.7 | 19 | 38 | 76 | 0.06 0.06 | 0.07 0.08 | 0.09 0.09 | 0.09 0.10 | 0.12 0.13 | 0.12 0.13 |

| 25 | 1 | 32 33.4 | 22 | 38 | 76 | 0.07 0.08 | 0.12 0.13 | 0.14 0.14 | 0.14 0.15 | 0.19 0.19 | 0.19 0.19 |

| 32 | 1¼ | 38 42.2 | 25 | 48 | 96 | 0.11 0.13 | 0.18 0.20 | 0.21 0.23 | 0.23 0.26 | 0.30 0.34 | 0.30 0.34 |

| 40 | 1½ | 45 48.3 | 29 | 57 | 114 | 0.16 0.17 | 0.26 0.28 | 0.30 0.32 | 0.34 0.37 | 0.45 0.49 | 0.45 0.49 |

| 50 | 2 | 57 60.3 | 35 | 76 | 152 | 0.27 0.29 | 0.45 0.47 | 0.57 0.61 | 0.62 0.65 | 0.85 0.90 | 0.85 0.90 |

| 65 | 2½ | 76 73 | 44 | 95 | 190 | 0.58 0.55 | 0.82 0.79 | 0.97 0.93 | 1.35 1.30 | 1.79 1.71 | 1.79 1.71 |

| 80 | 3 | 89 | 51 | 114 | 228 | 0.82 | 1.17 | 1.51 | 2.04 | 2.76 | 2.76 |

| 90 | 3½ | 101.6 | 57 | 133 | 266 | 1.09 | 1.56 | 2.03 | 2.85 | 3.92 | 3.92 |

| 100 | 4 | 108 114 | 64 | 152 | 304 | 1.32 1.40 | 1.90 2.01 | 2.47 2.61 | 3.64 3.85 | 5.05 5.35 | 5.05 5.35 |

| 125 | 5 | 133 141.3 139.7 | 79 | 190 | 380 | 2.67 2.84 2.81 | 3.27 3.47 3.43 | 4.74 5.05 4.99 | 6.14 6.54 6.46 | 8.72 9.31 9.19 | 8.72 9.31 9.19 |

| 150 | 6 | 168.3 159 165 | 95 | 229 | 458 | 4.10 3.86 4.01 | 5.01 4.72 4.91 | 7.29 6.88 7.14 | 10.24 9.64 10.03 | 15.41 45.50 15.09 | 15.41 45.50 15.09 |

| 200 | 8 | 219 216 | 127 | 610 | 7.12 7.03 | 9.63 9.49 | 15.94 15.71 | 20.51 20.22 | 31.17 30.71 | 31.17 30.71 | |

| 250 | 10 | 273 267.4 | 159 | 381 | 762 | 13.62 13.34 | 16.74 16.39 | 24.97 24.44 | 36.33 35.56 | 49.12 48.06 | 57.83 56.57 |

| 300 | 12 | 325 323.9 318 | 190 | 457 | 914 | 22.66 22.58 22.16 | 26.10 26.01 25.53 | 35.79 35.66 35.00 | 53.58 53.40 52.39 | 70.69 70.44 49.11 | 95.81 95.46 93.63 |

Tee

Norminal Diameter | Outside Diameter | Center to end | Approx weight | |||||||

| DN | NPS | D1XD2 | C | M | sch5S | sch10S | sch40 | sch40S/STD | sch80S | sch80XS |

| 125X90 | 5X3.1/2 | 141.3X101.6 | 124 | 114 | 3.09 | 3.83 | 7.39 | 7.39 | 10.6 | 10.6 |

| 125X80 | 5X3 | 133X89 141.3X73.0 | 124 | 111 | 2.90 3.02 | 3.59 3.74 | 6.92 7.21 | 6.92 7.21 | 10.0 10.4 | 10.0 10.4 |

| 125X65 | 5X2.1/2 | 133X76 141.3X60.3 | 124 | 108 | 2.85 3.00 | 3.59 3.73 | 6.92 7.20 | 6.92 7.20 | 10.0 10.4 | 10.0 10.4 |

| 125X50 | 5X2 | 133X57 141.3X60.3 | 124 | 105 | 2.80 3.92 | 3.58 3.73 | 6.92 7.20 | 6.92 7.20 | 10.0 10.4 | 10.0 10.4 |

| 150X150 | 6X6 | 159X159 168.3X168.3 | 143 | 143 | 4.09 4.32 | 5.03 5.31 | 10.5 11.1 | 10.5 11.1 | 16.2 17.1 | 16.2 17.1 |

| 150X125 | 6X5 | 159X133 168.3X141.3 | 143 | 137 | 3.84 4.13 | 4.73 5.08 | 9.88 10.6 | 9.88 10.6 | 15.2 16.3 | 15.2 16.3 |

| 150X100 | 6X4 | 159X108 168.3X114.3 | 143 | 130 | 3.76 3.95 | 4.64 4.87 | 9.70 10.2 | 9.70 10.2 | 14.9 15.6 | 14.9 15.6 |

| 150X90 | 6X3.1/2 | 168.3X101.6 | 143 | 127 | 3.91 | 4.82 | 10.1 | 10.1 | 15.5 | 15.5 |

.. | .. | .. | .. | .. | .. | .. | .. | .. | .. | .. |

900X400 | 36X16 | 920X426 914X406.4 | 673 | 559 | - | - | 335 287 | 669 575 | 447 383 | - |

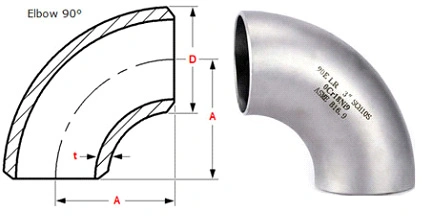

The 90 degree Long Radius Elbow manufactured using superior grade raw materials. The 90 degree Long Radius Elbows are used for connecting pipes of different diameters and find wide applications in various chemicals, construction industries, paper, cement & ship builders.

We have adopted advanced production equipment to make our 90 degree Short Radius Elbow(1D D711.2~D1219.2), which can not only improve product quality, but also save raw materials.

ASME B16.9 Butt weld 90 degree Long Radius Elbow Dimensions

ASME B16.9 90°Short Radius Elbow Dimensional Tolerance

NPS | O.D. | 90 degrees | 45 degrees | 90 degrees | 45 degrees |

1/2 | 21.3 | 38 | 16 | - | - |

3/4 | 26.7 | 38 | 19 | 57 | 24 |

1 | 33.4 | 38 | 22 | 76 | 31 |

1¼ | 42.2 | 48 | 25 | 95 | 39 |

1½ | 48.3 | 57 | 29 | 114 | 47 |

2 | 60.3 | 76 | 35 | 152 | 63 |

2½ | 73 | 95 | 44 | 190 | 79 |

3 | 88.9 | 114 | 51 | 229 | 95 |

3½ | 101.6 | 133 | 57 | 267 | 111 |

4 | 114.3 | 152 | 64 | 305 | 127 |

5 | 141.3 | 190 | 79 | 381 | 157 |

6 | 168.3 | 229 | 95 | 457 | 189 |

8 | 219.1 | 305 | 127 | 610 | 252 |

10 | 273 | 381 | 159 | 762 | 316 |

12 | 323.8 | 457 | 190 | 914 | 378 |

14 | 355.6 | 533 | 222 | 1067 | 441 |

16 | 406.4 | 610 | 254 | 1219 | 505 |

18 | 457 | 686 | 286 | 1372 | 568 |

20 | 508 | 762 | 318 | 1524 | 632 |

22 | 559 | 838 | 343 | 1676 | 694 |

24 | 610 | 914 | 381 | 1829 | 757 |

26 | 660 | 991 | 406 | 1981 | 821 |

28 | 711 | 1067 | 438 | 2134 | 883 |

30 | 762 | 1143 | 470 | 2286 | 964 |

32 | 813 | 1219 | 502 | 2438 | 1010 |

34 | 864 | 1295 | 533 | 2591 | 1073 |

36 | 914 | 1372 | 565 | 2743 | 1135 |

38 | 965 | 1448 | 600 | 2896 | 1200 |

40 | 1016 | 1524 | 632 | 3048 | 1264 |

42 | 1067 | 1600 | 660 | 3200 | 1326 |

44 | 1118 | 1676 | 695 | 3353 | 1389 |

46 | 1168 | 1753 | 727 | 3505 | 1453 |

48 | 1219 | 1829 | 759 | 3658 | 1516 |

ASME B16.9 90° Long Radius Elbow Dimensional Tolerance

| DIMENSIONAL TOLERANCES - ELBOWS | |||||||

| For all fittings | Elbows 90/45 deg | 180° Returns | |||||

| Nominal Pipe Size (NPS) | Outside Ø at Bevel | Inside Ø at End | Wall Thickness t / t1 | Center to End Dim. A-B-C-M | Center to Center Dim. O | Back to Face Dim. K | Align- ment of Ends U |

| 1/2 a 2 1/2 | 1 | 0,8 | Not | 2 | 7 | 7 | 1 |

| 3 a 3 1/2 | 1 | 1,6 | less | 2 | 7 | 7 | 1 |

| 4 | +2 -1 | 1,6 | than | 2 | 7 | 7 | 1 |

| 5 a 6 | +3 -1 | 1,6 | 87,50% | 2 | 7 | 7 | 1 |

| 8 | 2 | 1,6 | of nominal | 2 | 7 | 7 | 1 |

| 10 | +4 -3 | 3,2 | thickness | 2 | 7 | 7 | 2 |

| 12 a 18 | +4 -3 | 3,2 | 3 | 10 | 7 | 2 | |

| 20 a 24 | +6 -5 | 4,8 | 3 | 10 | 7 | 2 | |

| 26 a 30 | +7 -5 | 4,8 | 3 | ..... | ..... | ..... | |

| 32 a 48 | +7 -5 | 4,8 | 5 | ..... | ..... | ..... | |

An elbow is a pipe fitting installed between two lengths of pipe or tubing to allow a change of direction, usually a 180° or 90° angle, though 45° elbows are also made. The ends may be machined for butt welding (SW) or socketed welding(SW) etc.

Most elbows are available in short radius or long radius variants. When the two ends differ in size, the fitting is called a reducing elbow or reducer elbow.

Elbows are categorized based on various design features as below:

- Long Radius (LR) Elbow is also called LR elbow - means the radius is 1.5 times the pipe diameter

- L/R 45°Elbow: Long radius 45 degree elbow changes the direction by 45 degrees.

- L/R 90°Elbow: Long radius 90 degree elbow changes the direction by 90 degrees.

- L/R 180°Elbow: Long Radius 180 degree return bend allows complete reversal of flow.

- Short Radius (SR) Elbow is also called SR elbow, - means the radius is 1.0 times the pipe diameter

- Short radiu 45°Elbow: Short radius 45° elbow changes the direction by 45 degrees.

- Short radius 90°Elbow: Short Radius 90° elbow is same as LR90 except for the measurement between end of elbow to center line is 1 x NPS.

- Short radius 180° Elbow: Short Radius 180° return bend allows complete reversal of flow

Size range:

- Seamless elbow: 1/2"-24" DN15-DN600

- Welding elbow: 6"-72" DN150-DN1800

- Wall thickness: Sch5-Sch160 XXS